Cement and Construction

The cement and construction industries significantly contribute to the nation’s GDP, but face challenges such as working at greater heights, chaos, labourers carrying heavy materials, dust allergies and more. We address these challenges and provide solutions through RAAS (Robot as a Service).

Explore Our Products

Robotic Cement Cube Making Physical Lab

It is a fully automated robotic system for the making of cement test cubes, adhering to BIS 4031 standards. This system automates all critical steps in the cube-making process, including feeding, mixing, metering, pouring, vibration and levelling, with minimal human intervention.

- Integrated advanced robotics and automation technology

- Enhances accuracy, efficiency and safety

- Reduced human error and operational labour

- Ensured repeatability

- Consistent quality and high production efficiency

Idosemate - RMC Transit Life Enhancement (Upto 10 Hours) and Remote Quality Management System

The IDoseMate – Automatic Admixture Dosing System is an advanced solution designed to enhance the transit-life of concrete from the present 2 hours to 10 hours. Equipped with a smart pressure sensor, an admixture tank, a metering pump and the JANYU Controller with HMI, the system maintains the desired concrete workability during transit.

- Admixture dosage adjustment via an AI-based algorithm

- Reduced material wastage and site rejections

- Consistent quality and sustainable construction

- Real-time data via online monitoring capabilities

Robotic Preheater and Smoke Chamber Cleaning

The Automated Jetting System for Preheater/Smoke Chamber Cleaning is a high-pressure water jet lancing solution designed for preventive maintenance in furnaces operating at 1000°C and above. Equipped with a fully articulating robotic arm, the system offers multidirectional lancing movement – up, down, sideways, rotational, and backwards – allowing comprehensive cleaning coverage, including hard-to-reach areas.

- Remotely operated system with less manual intervention

- Automatic triggering based on critical parameters

- Enhanced operator safety and reduced downtime

- Precision-targeted jetting for efficient removal of buildup

- Reduced shutdown and avoidance of breakdown maintenance

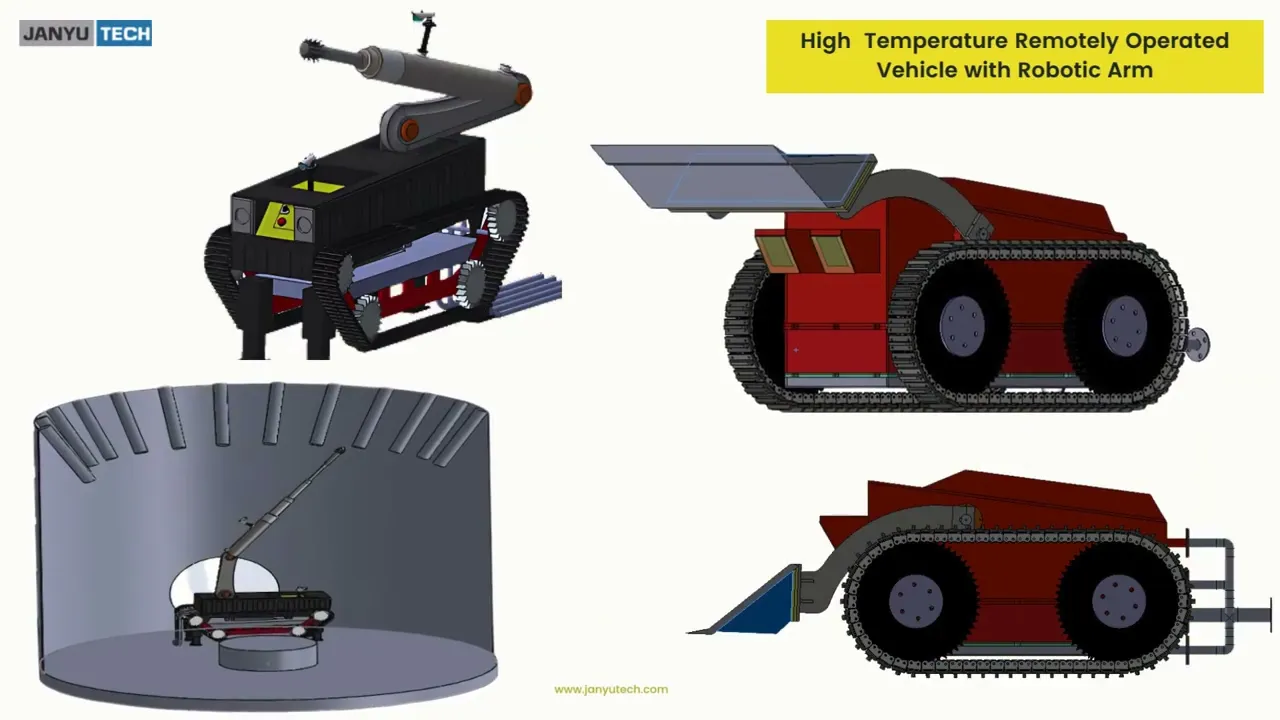

Rotary Kiln Internal Coating Robotic Removal System

Our THEE1200 Remotely Operated Kiln Choke Clearing Machine is an advanced solution designed to streamline and enhance the efficiency of kiln choke clearing operations. This semi-automated system minimises manual intervention, ensuring safer operations.

- Reduced need for personnel in high-temperature environments

- The robotic system can enter the Kiln chamber at 400-500° C

- Considerable reduction in downtime

- Enhanced operational efficiency

Automatic Concrete Cube maker

The Automatic Concrete Cube Maker is a strong, portable system engineered for precision and productivity in concrete sample cube making for testing. Designed to produce standard concrete test cubes on-site, it features a stainless-steel hopper, motorised screw conveyor and automated tamping with stroke control – ensuring consistent compaction per IS-10086 standards. The system operates via a user-friendly 7” HMI panel with programmable recipes and requires only a 230V power supply.

- Built for field conditions, it enhances safety

- Reduces manual error and accelerates testing workflows

- Ideal for construction and RMC sites

- Ensures reliable, consistent and repeatable results