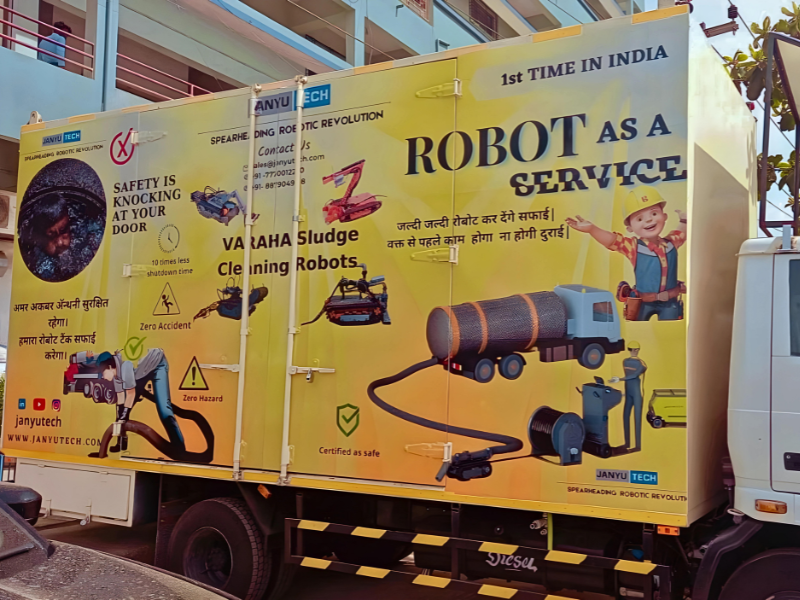

Robot as a service- RAAS

Sludge Cleaning Robot as a service

Sludge Cleaning Robot

Sludge is formed in an oil tank due to rust particles, oil residue, moisture, and other agents for bacteria. For that, humans must remove all oil from the tank, scrub the sludge, add cleaner, let the tank dry before refilling the oil, and use appropriate disposal methods in the absence of a robotic sewer cleaner.

Sludge treatment and cleaning is not a one-time process and humans must do it regularly. Similarly, if not done on time, it will accumulate in plug openings, pipe openings, and other areas of frequent use. In that case, humans are prone to health risks due to exposure to hazardous material caused due to sludge accumulation.

At JanyuTech, we understand this problem and provide sludge-cleaning robots, especially for the oil and gas industry.

RAAS- Sludge Cleaning Robot (SCE/SCH)

Our robotic cleaning solutions through Robot as a Service (RaaS):

- Robotic Sludge Cleaning Crawler System: It is powered by a compatible hydraulic power pack with a hydraulic hose reel.

- Suction Hose: To draw water from the source.

- Lateral Washing System (Including Handgun Arrangement): To deal with water coming from the lateral.

- Control Panel & Accessories: To offer automation in water pump systems.

- Vehicle Chassis With Cabin: It has a load body, side PTO - 7.2 Ton GVW/3800 wheelbase/BSVI (Scope of client).

RAAS UNIQUE VALUE PROPOSITION AND ECONOMIC ADVANTAGES

- Efficiency: The sludge cleaning robot is designed to efficiently remove sludge and debris from industrial open tanks, improving overall tank cleanliness and preventing clogs and blockages.

- Safety: It operates in hazardous environments, reducing the need for human workers to enter potentially dangerous spaces, enhancing workplace safety.

- Versatility: The robot can be adapted for various tank sizes and shapes, making it a versatile solution for different industrial applications.

- Automation: It operates autonomously, reducing labor costs and ensuring consistent and thorough tank cleaning, ultimately increasing productivity in industrial settings.

BENEFITS OF RAAS

- Services Covered: Offers maintenance, upgrading, and servicing of the robot.

- Implementation Simplified: Offers maintenance, upgrading, and servicing of the robot.

- Cost Efficiency: Cost targeted equivalent to a fully-burdened full-time employee.

- No CapEx Outlay: Lowers barriers to deployment due to no CapEx outlay.

- Immediate Return on Investment (ROI): Immediate customer ROI due to increased productivity.

- No Obsolete Technology: We offer software updates with overall service management.