Concrete-Cement Automation

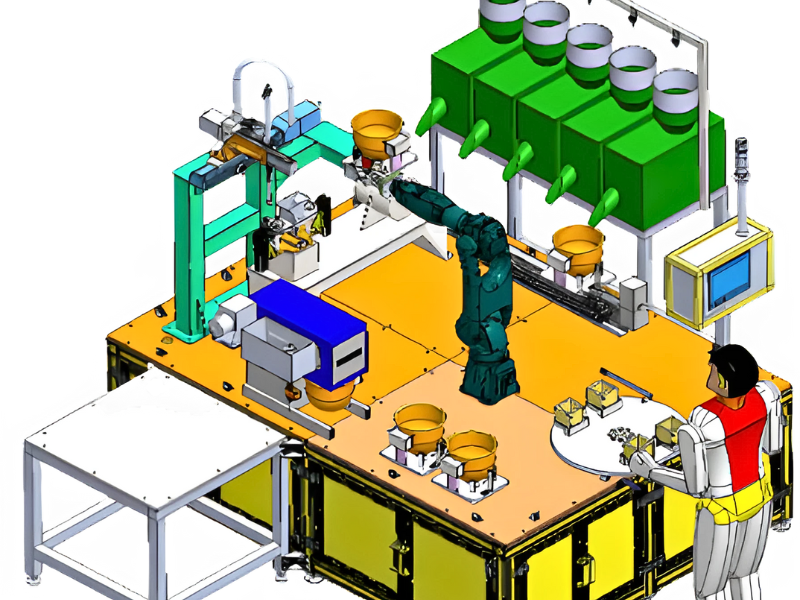

Concrete Cube making Robots

Cement Cube Testing Lab

Efficiency Boost:

Robotic arm streamlines compression tests, ensuring swift and accurate results.

Precision Handling:

Reduces human error, guaranteeing consistent data recording.

Enhanced Safety:

Minimizes exposure to hazardous materials, prioritizing lab personnel well-being.

Time Saver:

Speeds up testing processes, facilitating quicker analysis and decision-making.

Cutting-edge Technology:

Represents a contemporary approach to cement testing, aligning with industry advancements.

Versatile And Adaptable:

Easily integrates into various testing protocols, offering flexibility in lab operations.

Ready Mix Concrete Cube Making Robot

Efficient Production:

Automates the production of concrete cubes, streamlining batching, mixing, and molding processes.

Quality Assurance:

Ensures consistency in cube production, facilitating precise assessment of concrete strength.

Reduced Human Error:

Minimizes potential errors associated with manual cube-making methods, enhancing accuracy.

Standardized Testing:

Enables standardized compressive strength testing to evaluate concrete quality effectively.

Enhanced Reliability:

Provides reliable and repeatable results for assessing concrete batch quality.

Industry Compliance:

Helps ensure compliance with required specifications and standards in the construction sector.

Transit Mixture Doser

Automated Precision:

Executes precise dosing operations autonomously, minimizing errors and optimizing chemical usage.

Uniform Dispensing:

Ensures uniform mixing of additives, enhancing product consistency and quality assurance.

Error Reduction:

Drastically reduces the likelihood of human error, enhancing reliability and repeatability in dosing tasks.

Seamless Integration:

Easily integrates into existing production lines without disruption, streamlining workflow and improving operational efficiency.

Productivity Enhancement:

Boosts productivity by optimizing dosing processes, leading to increased throughput and reduced downtime.

Cutting-edge Solution:

Represents the forefront of chemical dosing technology, providing innovative solutions for industries such as pharmaceuticals, food processing, and chemical manufacturing.

Concrete Cube Making Robot

Efficiency and Precision:

Streamlining the cube-making process with remarkable efficiency and precision, ensuring accurate cube dimensions and strength.

Automation:

Featuring automated operation, eliminating the need for manual labor and ensuring consistent cube quality.

Reliability:

Enhancing the reliability of concrete quality assessments, contributing to safer and more dependable construction projects.

Cutting-edge Technology:

Incorporating cutting-edge technology to accelerate cube-making processes and improve overall construction efficiency.

Compliance:

Ensuring compliance with industry standards and regulations for quality control and testing procedures.

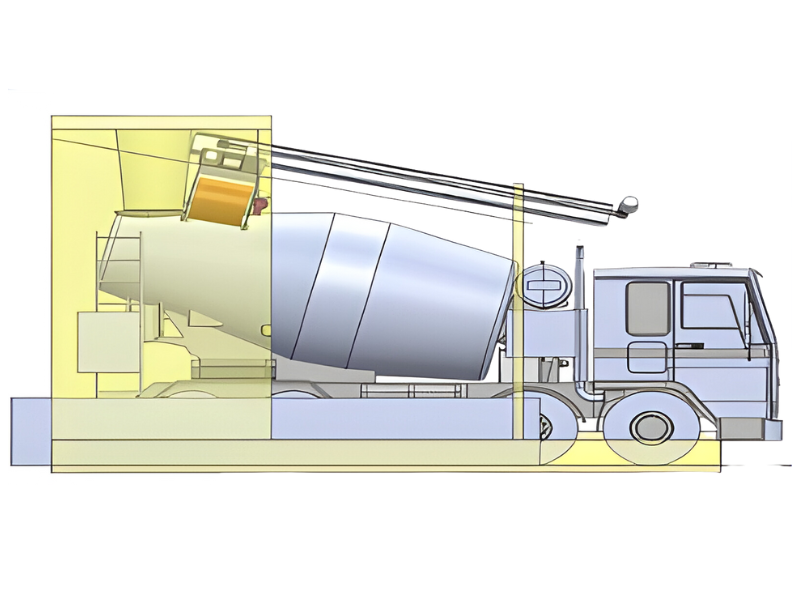

Transit Mixture Cleaner

Efficient Cleaning:

Utilizes powerful water jets and brushes to remove residual concrete, maintaining optimal cleanliness.

Preventive Maintenance:

Eliminates hardened concrete buildup, preventing future quality compromises in concrete batches.

Enhanced Productivity:

Ensures transit mixers are consistently clean, minimizing downtime and maximizing operational efficiency.

Equipment Longevity:

Extends the lifespan of transit mixers by preventing corrosion and damage caused by concrete residue.

Quality Assurance:

Contributes to the production of high-quality concrete batches by ensuring the cleanliness of mixer drums.

Indispensable Tool:

Integral to the construction process, supporting productivity, equipment maintenance, and concrete quality.