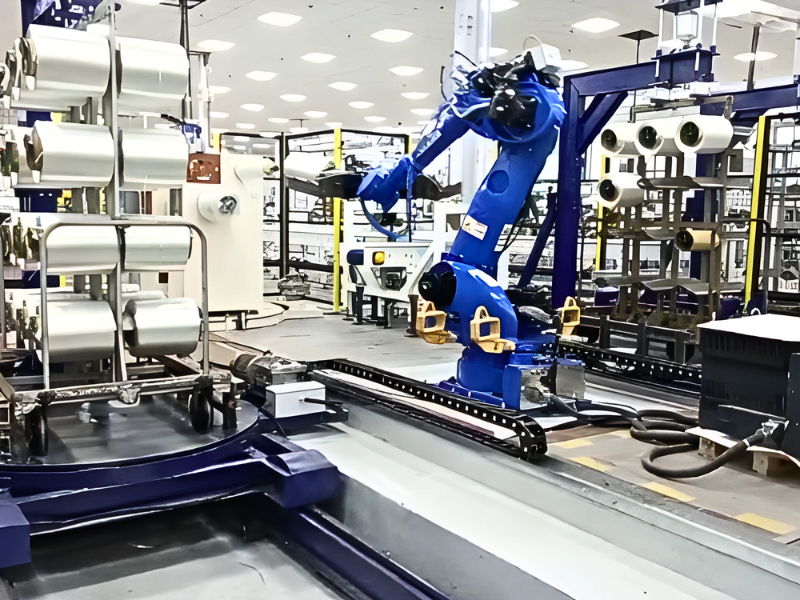

Industrial ROBOTIC ARM Automation SERIES -'KARA'

Robotic Arm pick & place

- Automated Warehouse: For material handling.

- Robotic Palletizing: To stack goods onto a pallet.

- Automated Guided Vehicles (AGVs): For Material Handling.

- ASRS: To store or retrieve goods from specific locations.

- Customized Software: To meet client's requests.

- System Integration: To get automated solutions from the robots.

Denka Arm Robot

- Category: Petrochemicals.

- Palletized Bag: Handling of 25kg bags to stack and arrange products.

- Bags Are Robotically Loaded Onto Pallets.

- Tracking The Bags: Tracking occurs with the barcode.

- Pallets Are Tracked Using An RF Code: For real-time asset tracking.

Robotic Material Handling

- Precision Handling: For accurate crate placement.

- Controlled By Programmable Logic Controllers (PLCs): For seamless coordination.

- Robotic Material Handling Equipment: Adaptable to various crate sizes and weights.

- Optimizes Efficiency: Shortens cycle times, and decreases labour costs.

- Improves Workplace Safety: By reducing manual handling dangers.

- Reliable Performance: Simple integration with current production lines.

- Intuitive Controls: For user-friendly operation with robots PLC.

- A Flexible Solution: For many pick-and-place jobs.

FACTORY & WEARHOUSE AUTOMATION

Material Handling Robot - SUKI

- Navigates Complex Settings: By avoiding barriers and optimizing pathways.

- Interfaces With Central Systems: Delivering real-time information about material movements.

- Works Together With Human Workers: To improve overall material logistics efficiency..

- Efficiently Organizes Inventory: Optimizes storage space.

- Easily Integrates Into Assembly Lines: To handle components and finished products.

Material Handling Robot - CUBE

Increases productivity:

With AMRs, workers do not have to spend time walking around to deliver goods. Workers can focus on more high value tasks.

Lower labour costs:

You need fewer workers to achieve the same (or higher) productivity when compared to manual operations.

Increased efficiency:

AMRs are not subjected to human errors or inconsistency brought about by absenteeism, stress, tiredness or inexperience.

Increased safety:

AMR can replace workers for high risk delivery jobs that possibly cause injury. AMR are designed as a highly responsive robot to work dynamically with their environment.

Increased flexibility:

AMRs route and task can be easily modified using NavWiz AMR software for any changes of delivery operation.

Quick and easy to implement:

AMRs can be deployed within an operation in about 1 to 6 weeks, or even faster depending on the number of AMR and integration complexity.

Material Handling Robot - ZETHA

Increases productivity:

With AMRs, workers do not have to spend time walking around to deliver goods. Workers can focus on more high value tasks.

Lower labour costs:

You need fewer workers to achieve the same (or higher) productivity when compared to manual operations.

Increased efficiency:

AMRs are not subjected to human errors or inconsistency brought about by absenteeism, stress, tiredness or inexperience.

Increased safety:

AMR can replace workers for high risk delivery jobs that possibly cause injury. AMR are designed as a highly responsive robot to work dynamically with their environment.

Increased flexibility:

AMRs route and task can be easily modified using NavWiz AMR software for any changes of delivery operation.

Quick and easy to implement:

AMRs can be deployed within an operation in about 1 to 6 weeks, or even faster depending on the number of AMR and integration complexity.